Biogas - a viable source of energy

Public forum on biogas:

by Indeewara Thilakarathne

[email protected]

The Public Forum on biogas which was recently held at Goethe

Institute in Colombo was an eye-opener to Sri Lankans especially with

the energy crisis looming in the horizon, as prices of crude oil surges

in the world market.

|

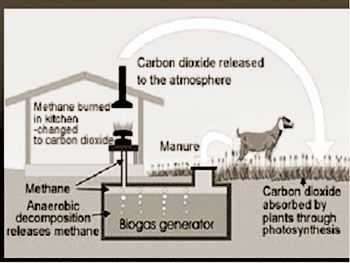

Biogas plant |

It is pertinent to ponder on whether Sri Lanka has harnessed its bio

potentials for generation of energy which according to Prof. KDN

Weerasinghe of the University of Ruhuna who made a presentation on

biogas, is capable of generating 30 per cent of energy requirement of

the country.

In the presentation, Prof. Weerasinghe pointed out that Sri Lankan's

perception of biogas is very narrow and potentials of biogas, bio-fuel

has not been adequately explored. Bio gas technology which is getting

wider popularity in developed and developing countries including India,

China, European union etc. as a green energy source seems to create a

big revolution in the years to come as a viable option to address the

world burning issues in the energy and waste management sectors.

The potential of the bio gas technology among the other green and

clean energy sources such as ethanol and bio diesel, is enormous since

it could have three fold fronts to address the energy crisis by

resolving the mess in waste management while producing energy and

organic fertilizer for agriculture without leaving any traces of harmful

by products which can add to the environment degradation. It also gives

a solution to reduce the methane to the environment as a harmful

greenhouse gas.

Bio gas is produced as a result of a simple bio technology, which

does not use any chemicals or hazardous materials other than exploiting

naturally existing anaerobic bacteria. In other words it is the

harnessing and accelerating of a naturally existing bio-technology

process for our benefit.

Sri Lanka is in much convenient position to grab the advantage of

technology with a little input to be frontiers in bio gas technology

adoption programs to meet our burning problems in energy, waste

management and fertilizer production.

|

Biogas process |

Bio gas is a mixture of gases liberated by the methanogenic bacteria

as a result of their act on the organic products. These bacteria has an

ability to decompose complex organic materials in an oxygen free

environment to get the energy for their survival by liberating bio gas

as by products. Methane, Carbon dioxide and some tracer gases of

hydrogen sulphide, Ammonia and water vapour and nitrous oxide as a

mixture is included to the composition of it.

When organic wastes are kept in a container without having any

exposure to atmospheric oxygen Methanogenic bacteria works on them

producing bio gas which has about 50 to 70 per cent of methane.

This can be simply burned out in the kitchen to get energy for

cooking. By converting methane in to carbon dioxide which is 26 times

less harmful green house gas compare to methane. When organic wastes

such as domestic and farm wastes, weeds, animal excreta or any other

complex organic materials are subjected to bio-methanation process,

energy and fertilizer production is simultaneously taking place.

Bio gas technology was introduced to Sri Lanka in seventies by the

Dept of Agriculture under the leadership of Mr. Upawansa. Since then

number of Research and development institutions were engaged with the

bio gas research and development work.

The widely constructed bio gas plants in Sri Lanka are Chinease,

Indian and Batch types.

The basic differences of the Indian and Chinease type digesters are

associated with the difference technologies adopted for gas collection.

In case of the Chinease digester it is a dome type construction out of

the bricks for gas collection. In the indian type digester there is a

metallic gas collector on the top.

Batch type biogas generators introduced by the NERD centre are being

used for bio-gasification of rice straw for household energy needs in

rural areas in Sri Lanka. The popularization of this technology among

people was very slow in the initial stages due to the construction cost.

However at present it gains popularity among rural communities as an

environmental friendly energy generation technology to acquire the rural

energy needs and fertilizer needs.

ITDG South Asia ( now Practical actions ) started a project on

developing and popularizing biogas technology in 1996 by carrying out a

sample survey to find out the status of biogas technology with a view to

learn lessons from the past experiences.

Department of Agric. Engineering Faculty of Agriculture,University of

Ruhuna in University of Moratuwa, Intermediate Technology Development

Group, ( ITDG ) South Asia and Energy Forum have initiated number of

Research and development project, on adoption of Bio Gas Technology

since 1990.

A research program to study the biogas liberation pattern from small

digesters, quality of the digested material as organic fertilizer,

social acceptance of the systems by Rural communities, Etc. were the key

areas of research conducted different organizations.

Batch type digesters developed by NERD centre and Chinese type

Digesters of domestic scale (1 -1.5 Ton capacity) were intensively

studied under different programs.

The general objectives of the research programs were to popularize

biogas and the by products of the bio-methanation as a viable

alternative source for resource poor people to meet their energy and

fertilizer needs. AS the results more than 5000 small scale bio gas

generators are installed in Sri Lanka.

Composition and the volume of biogas liberation from agricultural

waste (Paddy straw* ) *total estimated amount of annual rice straw

production, which were burnt or manure, is about 2860000 metric tones.

This is equivalent to 2.8 mln m3 of biogas which can meet the energy

demand of 1 mln houses, As such large amount of energy could be

generated from straw while mitigating the methane emission.

The research program conducted during 1999 to 2001 in the Sri Lankan

batch type biogas generator with 1 ton of straw (volume 6m3), helped to

establish that average gas production from the digester as 1.0 m3/day

with a peak value of 1.8 m3/day.

Total gas production during four and half month period of digestion

was 166.85 m3 with the maximum average methane percentage of 50%.

Fertility enhancement of Rice fields through the application of

anaerobicaly digested straw from batch type biogas generators, while

mitigating metane emission.

It was revealed in the experiments that application of digested straw

through biogas generator as an effective measure to increase the yield.

The yield increment from digested materials is high as twice compared

to direct straw application. NPK content of the digested materials of

straw coming out from the Sri Lanka batch type biogas generators was

found to be 1.9%, 0.14%and 1.6% respectively, which is about 50%, 35%,

30% high in NPK compared to NPK content of the straw.

It was established that the application of digested straw through

biogas generator as an effective measure to increase the yield. The

yield increment from digested material is as much as twice compared to

the direct straw application as a fertilizer.

Challenges Sri Lanka faces The bio gas technology is widely used in

Developed countries for electricity generation using agricultural wastes

and municipal garbage. It is accepted as a green energy source to combat

waste management problem.

The technology is well developed and number of large Research

institutions and companies are working in the bio gas area. This

technology can be easily transferable to Sri Lanka to combat challenges

in energy sector. One of the challenges that Sri Lanka faces is to move

from initial stage of small unite of bio-gas plants to medium size

commercially viable bio-gas plants which is capable of producing

electricity.

One of the bottlenecks identified in the forum in this regard is the

setting up of small and medium enterprises that would take up the task

of collecting bio-waste and producing electricity and bio-gas for

cooking.

It has also pointed out that government intervention in terms of

encouraging municipal councils, urban councils and Pradeshiya Sabhas to

set up medium or large scale bio-gas plants for generating electricity

with a view to solve the problem of garbage disposal.

In addition, producing bio-gas, the process will yield rich organic

manure which can also reduce present dependency on chemical fertilizer

for agriculture. Green products have a high demand in the export market,

thus opening up a lucrative environment-friendly avenue for generating

much-needed foreign exchange. This will, in the long rung, help reduce

rural poverty and unemployment. |