ITI project adds value to fish waste

A total of 50-60 percent of the annual fish harvest is discarded as

fish waste or by-products due to the processing methods practiced by the

industry. This leads to environmental problems and disturbance of off

shore fishing activities.

Fish heads, viscera (gut) gills, skin and fins are discarded as fish

waste. ITI and with the Norwegian Institute of Fisheries and Aquaculture

Research under a NORAD funded project commenced a project to find

methods to add value to fish waste.

Prior to the implementation of the project the fish waste collected

in the harbours too were dumped into the sea causing environmental and

other problems. Prior to the implementation of the project the fish waste collected

in the harbours too were dumped into the sea causing environmental and

other problems.

At the Beruwela harbour alone 700 kilos of waste per day was thrown

to the deep sea and it is no different to other harbours. After the

conflict, Kalmunai has a waste accumulation of 500-2,500 metric tons per

day depending on the season, said Research Scientist ITI, Samantha

Madage.

The ITI researched on methods to add value to the waste depending on

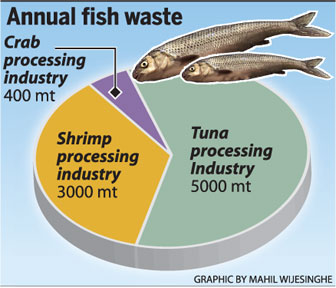

the quality and type of the waste. Madage said that the tuna processing

industry discards 40-50 percent as waste or by-products of which 30

percent can be consumed by humans which includes off cuts and the red

meat.

All this is sold to buyers in bulk form where the offcuts are dried

to be used as dried fish while the balance is dumped on bare lands or to

the sea.

Even poor quality and un fit for human consumption parts can be used

to produce animal feed and feed ingredients including fish silage, an

alternative to fish meal. Earlier there was no production of fish meal

locally therefore the total requirement had to be imported which was a

huge drain on foreign exchange. It is a major protein source in animal

feed and is very expensive.

The basic quality imported fish meal is Rs 340 a kilogram. Every part

of the fish can be used to manufacture fish silage which comes in liquid

form, which is a diet for pigs, poultry and fish.

The advantages of manufacturing fish silage locally are many. The

investment as well as the cost of production is very low, said Madage.

ITI has transferred this technology to the Beruwela harbour and has

further developed it as a powder using another waste material - rice

bran. It can be added to any form of feed. Other products which the ITI

has developed include bone meal, bone powder, gelatine from tuna skin,

fish oil, designer eggs and fish balls.

Madage said that some of the processes are patented while some

technologies have been transferred to companies for commercial

production.

Most of the technologies developed by the ITI are on low investment,

therefore even a small-scale entrepreneur can purchase and start

commercial production which will save foreign exchange and make the

country more environmental-friendly.

SG

|