|

SciTech

Better grip for tractor tyres

by Dhaneshi YATAWARA

Having an economy largely based on agriculture, Sri Lanka needs

accelerated developments in the field, particularly in agricultural

engineering. The attention of experts seems to be on the increase at

present. It needs more and not less if we are to be on par with the

global changes.

From primitive method to the new hi-tech |

|

|

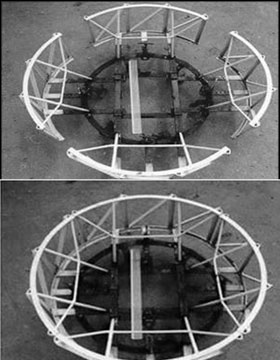

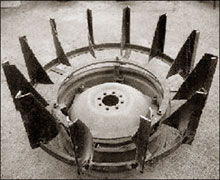

| Folding type

mud wheel |

Different types of new mud wheels to suit varying

soil conditions |

| |

Food production needs to be improved and we should reach a level to

be self sufficient as a nation. Sri Lankan agriculture needs a facelift.

Rice being our staple food, increase in its harvest has a greater impact

on the food production. Rice is the staple food of 19 million Sri

Lankans. According to statistics, 1.8 million farmers live on paddy

cultivation. Over 7.3 million hectares are cultivated annually for paddy

production in the country. However, due to low productivity farmers have

not been able to supply the demand for rice in the country.

Adding value to this competitively emerging field the innovation of a

folding type cage wheel for tractors developed by Dr. P.L.A.G. Alwis of

the Faculty of Agriculture, University of Ruhuna can improve the grip of

the regular rubber tyres of small and medium power tractors. Small and

medium tractors became an important factor in paddy cultivation as an

attractive alternative for land preparation using buffalo - the poor

man's tractor. It can be due to the dwindling of the buffalo population

or sociological factors.

This new cage wheel developed under a project funded by the National

Science Foundation, can be considered as an important development for

the farming sector. The use of this cage wheel comes in two folds - it

can improve the use of tractors in wet land paddy field operations and

in road transport.

"A tractor with ordinary high lugged rubber tyres works poorly in

wetlands due to slipping and sinking. To overcome this problem,

different types of gripping aids have been introduced including chains,

tracks and cage wheels," Dr. P.L.A.G. Alwis said explaining his

invention.

According to Dr. Alwis the technicians identify that the working of a

tractor depends on a number of factors - the soil surface on which the

tractor operates being the main factor deciding the efficiency of the

equipment.

But conventional "Mud wheels" for a four wheel tractor have smaller

outer diameter than the tyre to facilitate road transportation.

Therefore when operating in the fields tyres touch the hard pan first

and high slip takes place. Resulting a high travel reduction with

additional time spent on the work including wasting fuel and man power.

This is a considerable economic loss for farmers and tractor owners

and because of this I thought of designing and constructing this new

folding type cage wheels especially with my experience in France during

my PhD studies," the engineering inventor added explaining the pros and

cons of the old machines.

The invented mud wheel consists basically of four foldable folders

and inner mounting system. Each folder has outer cage and three parallel

bars.

Rectangular and angle lugs are fixed to the outer cage of a folder.

The inner mounting system consists of inner ring which is fixed to six

legs and cross bars. Four foldable folders are arranged circularly on

inner mounting system. This gives the capability to have a larger

diameter inthe field operation and smaller on road transportation.

Spring loaded key mechanism has provided to lock the folders at folded

and un-folded position.

The four wheel tractor equipped with the designed cage wheel had 60%

more field capacity and 28% more travelling speed when compared with the

conventional cage wheel. The time taken to plough a hectare of land was

decreased by 40% with the developed new cage wheels. Travelling time was

also reduced by 14%.

The newly developed cage wheel has a quick mounting and dismounting

system. It also gave an improved grip while ploughing fields as the cage

wheel diameter was greater than the type in the expanded position. This

folding type cage wheel can considered as a new aid for small and medium

sized tractors used in both high and wet land conditions. The cage wheel

has simple construction, good serviceability, high field performance in

different soil conditions and low cost.

Rapid prototyping tech quick and cost effective

by Harshini PERERA

Moulds built by the Rapid Prototyping machine |

Technology enables a nation to get into the state of development at

any time. More than any other country, Sri Lanka should take necessary

approaches to reach high in technology. Rapid Prototyping is also one

such measure of technology. The University of Moratuwa has signed a

tripartite agreement with Ministry of Industries and the National

Science Foundation to equip the Engineering Design Centre with a Rapid

Prototyping technology. This is said to be the first machine in Sri

Lanka through which a designer can present his product in complete form

to a potential client or to develop high end products that are required

for specialised industries such as medical and aircraft.

The facility has cost Rs. 40 million for which the Ministry of

Industrial development provided Rs.15 million and the balance Rs.25

million by the National Science Foundation out of the 2008 budget

allocations.

Rapid Prototyping is a technology where the data is fed to the

computer through software known as Computer Aided Design (CAD). Then the

initial three dimensional appearance of the prototype is designed and

fed to the computer in the machine. Inside the machine there lies a VAT,

(a vessel) containing a polymer liquid in which the structure of

prototype is created when the laser beam is placed on it. The structure

is built on a platform on the supportive parts where it is created layer

by layer. Therefore, liquid turns into solids with the application of

light. Later, the supportive parts are extracted using a chemical.

Finally, the prototype is put into UV oven to make it solid.

The service of this technology was available since 19 December 2008.

It was established with the hope of enhancing the design and manufacture

capabilities in electrical and electronic industry. Accordingly, not

only the industry, but many industries which require prototyping

technology such as gem and jewelleries, automobile, ceramic can rely on

it as well.

|

Rapid Prototyping machine |

This prototyping facility addresses the need of designer in supplying

the prototype more quickly and cost effectively. For instance, if a

designer wants to create the prototype built according to his

imagination with metal or wood, it would take two to three months

whereas this machine could do it within a maximum 26 hours. The Director

of Engineering Design Centre, Eng. B.S. Samarasiri explained that this

prototype can be used as the mould as well as the real product. "These

prototypes can also be used as final products as in hearing aids and

medical applications. Because of the high quality they come out which

makes it easy. We have found out that they can produce any prototype

whether it is simple or complicated. This facility was imported from

Germany and an awareness program on this technology was conducted by a

German engineer," he further added.

Eng. Samarasiri explaining further said that, they have already

agreed to render service to Loadstar, Dankotuwa Porcelain, Alankara SKR

(Pvt) Ltd. and LECO for their requests for prototypes." NSF, UOM and MID

has decided to convey a 50% concessional price applicable to all small,

medium and large (Employment above 50 workers) industries for the

servicing of the machines.

We also consider the need of national award winners and one who has

registered with the inventor's commission for the concessional price,"

he stated.

This technology brings sophisticated method to the designers and

inventors deviated from classical methods of making modules. It enables

many with research approaches and profitable approaches to market their

products quickly and reasonably. At the same time since it is based in

an educational institute, the technology can be efficiently transferred

to the students.

South Asia's largest rivers threatened, warns UN

Water resources in three of South Asia's largest river basins are

highly vulnerable, with millions of people at risk of increasing water

scarcity, a new report has found.

|

The River Ganges |

The report - jointly released by the UN Environment Programme and the

Asian Institute of Technology - studied the Ganges-Brahmaputra-Meghna (GBM),

Indus and Helmand river basins, all of which span multiple countries

within the region. It lists overexploitation, climate change, and

inadequate distribution and use of water resources among the key threats

to the three basins, calling for "a unique mix of policy interventions

and preferred routes for future water resources development" to tackle

these challenges. Jinhua Zhang, regional coordinator at the UNEP

Division of Early Warning & Assessment told SciDev.Net that countries

should cooperate more to improve how water resources are managed -

particularly to control pollution and improve efficiency - to help stop

further damage to these rivers.

The report assigned each river basin a vulnerability index, based on

resources stress, development pressure, ecological health and management

challenges. The GBM basin is most vulnerable, but water resource systems

in the Helmand and Indus basins are also highly vulnerable.

Extreme population growth in the basins over the last century has put

pressure on the region's water resources, while around two-thirds of the

Himalayan glaciers that feed the basins are receding. Additionally,

groundwater levels in the GBM and Indus basins are declining at a rate

of two to four metres per year due to intense pumping.

In India alone the amount of water per head has decreased from 4,000

to 1,869 cubic metres in the last twenty years.

Zhang told SciDev.Net that further research is needed to identify the

supply of glacial melt for a given area, the amount of wastewater

generated by industry, and strategies for water treatment.

"The per capita availability of freshwater is declining, and

contaminated water remains the greatest single environmental cause of

human illness and death," he says. Improving our knowledge of the

vulnerability of freshwater resources "is therefore essential so that

policymakers can manage this vital resource for the benefit of their

people, their economies and the environment,'' says Zhang.

The report was released this month and is the first of a series. UNEP

is doing similar assessments in North East Asia and South East Asia.

(Source/SciDev.net)

For high quality 'blacklime'

ITI takes valuable steps:

|

The modified dryer

|

Research Officer Neville Amunugoda

|

Food technology in Sri Lanka is at a dire need of significant

developments strong enough to make a difference. Rich with a wide

variety of fruits, vegetables and world renowned spices grown in optimum

weather conditions, Sri Lanka has a promising future in the most

competitive world food market, along with a technology to level up the

product quality.

Identifying this requirement Industrial Technology Institute of Sri

Lanka, recognised to be a centre of excellence in the area of Food

Technology, has taken number of steps in promoting national food

security and safety.

Black Lime

Following these steps Neville Amunugoda, Research Officer attached to

the Food Technology Unit of the ITI designed and constructed a rack

drier which can convert perishable lime in to a product called `Black

Lime' or dried whole lime. This has a high export potential especially

to the Middle Eastern countries as a spice.

According to the Internet in the world this dried lime is also known

as Loomi, Lumi, Omani and Amani. This is a spice used in Middle Eastern

dishes. According to traditions this black lime is made by boiling fresh

lime in salt water and drying it.

Black limes are usually used in legume, seafood or meat dishes. They

are pierced, peeled or crushed before adding them to the dish. After

cooking they become softer and edible. They can also be powdered and

added to rice dishes.

Powdered black lime is also used as an ingredient in Gulf-style `baharat'(a

spice mixture which is also called `kabsa' or `kebsa'). It is very

popular in the Middle East.

Black limes are strongly flavoured. They taste sour and citrus like a

lime but they lack the sweetness of fresh limes. Because they are

preserved they also have a slightly bitter, fermented flavour.

A promising industry

In Sri Lanka manufacturing black lime for export is a promising field

in the food industry with great potentials in the world food market.

Having a rich harvest of high quality lime, especially in the Dry Zone,

is a highly favourable condition for this industry.

"A large amount of energy is required to dry lime. To make black lime

farmers have to adhere to certain quality levels of the end product and

to that lime can not be sun dried," Neville Amunugoda added.

This high energy is required to generate the heat to dry lime. In

Amunugoda's invention this temperature required drying lime is generated

by combustion of biomass.

As the researcher explained the present practice is to use electrical

dryers to dry lime, which is costly for a medium or a small scale

industry. Hence, biomass combustion can be a better solution since dry

flammable agro waste is widely available in the fields.

The problem of using biomass is its smoke with unburnt carbon

particles. This can lower the quality of the black lime. Addressing this

problem Amunugoda found a solution to bring out a non-smoke dryer. This

equipment can handle 60kg of lime at a time.

FT division

The ITI Food Technology division assists food industries by

developing or adapting existing technology, providing necessary

technical support providing machinery and equipment, providing

assistance with identifying unit operations and establishing processing

lines, and engaging in trouble shooting and other forms of consultancy.

The scope of the unit also extends to the vital area of developing and

promoting the production and distribution of nutritional and

nutritionally enriched food in both rural and urban backgrounds.

The section also conducts research programs in the above areas, with

applied problems being handled by multidisciplinary teams. These results

and research findings provide income-generating opportunities for small

and medium industries and are also transferred to industry partners for

larger commercial operations. The FT Section conducts a range of

training programs to meet various needs of the food industry, including

the supervision of Undergraduate and Postgraduate students from national

and international universities. In doing so, the unit also develops

human resources for the industry at large.

Over the years the Food Technology Section has built up a reputation

of expertise in the fields of cereal and bakery technology, Fruit and

Vegetable Processing and Post Harvest Technology, Fish Processing and

Waste Utilization Technology as well.

DY

|