RRI, the driving force of the rubber industry

by K.K.D. Premalal - Matugama Daily News Special Cor

Many products made of rubber are available for safety, comfort,

protection and pleasure. Teats, balloons, balls, bathing caps, condoms,

tyres, toys, erasers, inner tubes, cast products, slippers and shoes are

some of the products manufactured using rubber. The rubber industry is

the second largest industry in the world after iron and steel.

|

Dr. Priyani Seneviratne, Head, Plant Science Department of the

RRI. |

|

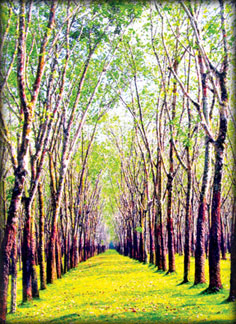

A rubber plantation |

In England, Joseph Priestley, best known for his discovery of oxygen,

noted that pencil marks could be "rubbed out" by the substance. From

this early use, rubber derived its name.

Vision

The rubber tree (Hevea brasiliensis) has a smooth bark, compound

leaves and small inconspicuous flowers. The seeds are akin to castor

beans.

On ripening , the fruit explodes and propels the seeds away from the

trees. The motherland of the rubber tree is the Amazon jungle in South

America. With the discovery of vulcanisation and other technological

advances, the demand for rubber has increased.

In the 1870s Brazil was the only producer of rubber to the world

market. Sir Henry Alexander Wickham is the man who introduced rubber to

Sri Lanka and other Asian countries.

The first rubber tree was planted in 1876 at Henarathgoda Botanic

Gardens.

The Rubber Research Institute of Sri Lanka (RRI) in Agalawatte is the

driving force of the oldest of its kind in the world. Research carried

out for more than a century has provided us a wealth of knowledge and

information on new technologies to improve the productivity of rubber

lands and development of numerous types of rubber products. Today a

large number of scientists and supporting staff work tirelessly at the

institute developing new clones, improving agro management practices and

innovating technologies for raw rubber processing and products. Some of

the clones developed by the RRI has won international recognition for

their productivity and resistance to various kinds of diseases.

The vision of the RRI is to emerge as the centre of excellence in

providing high quality scientific technologies to the rubber plantation

industry. According to the Rubber Research Ordinance, the Rubber

Research Board under the Ministry of Plantations is the governing body

of the RRI of Sri Lanka.

Rubber-Rice Pact

A devoted and dedicated staff functioning under 17 departments and

units have a mission to revitalise the rubber sector by developing

economically and environmentally sustainable innovations and

transferring the latest technologies to the stakeholders through

training and advisory services.

The RRI in Agalawatte, is about 15 kilometres away from Matugama on

the Agalawatte Road. It is surrounded by dense rubber plantations on

moderately hilly terrain.

The site provides a conducive environment for scientists to carry out

their research work.

The zig zag route leading to the destination is a pleasant sight

indeed. The RRI is a "must see" for those interested in learning about

this wonderful tree and the huge industry based on its products.

The origin of research of rubber goes back to 1909, when a group of

planters in the Kalutara district met and agreed to engage a chemist to

study the coagulation of rubber.

This marks the beginning of scientific research on national rubber in

the world.

Various research has been made ever since towards the development of

the rubber industry. The RRI has emerged as one of the leading research

organisations with international reputation.

In the early 1950s Sri Lanka faced a rice crisis and there was a

considerable escalation of its price in the world market. It was in this

grim setting, the historic Rubber-Rice Pact between Sri Lanka (then

Ceylon) and the People's Republic of China was signed in 1952. R.G.

Senanayake, the then Minister of Trade and Commerce signed the pact with

his Chinese counterpart.

Senanayake found that China was ready to give rice to Sri Lanka in

exchange for rubber. The Ceylon - China trade agreement is undoubtedly

the most useful one signed by both countries. On the other hand, this

was the first trade agreement signed by China with a non-communist

country. This year marks the 61st anniversary of the historic

Rubber-Rice Pact between Sri Lanka and China. The RRI's Plant Science

Department Head Dr. Priyani Seneviratne said, "We have introduced a new

system for planting rubber in home gardens using rubber clones with high

productivity. This will help earn an extra income for families who

possess small home gardens. The distance between two trees should be 20

feet and it will certainly help cultivators to produce high quality

rubber latex. Therefore, if a family owns 10-15 of such trees, a good

income is guaranteed over a long period of around 25 years. Having a few

such trees in the home garden would be a kind of an insurance scheme for

the family as the crop can be obtained when the need arises.

In other words, rubber is one of the privileged trees which can store

the crop within , for the farmer to utilise when he is in need of it.

The RRI is prepared to give clones to cultivators and provide them with

instructions.

She said, "A program has been launched to cultivate rubber in the

Northern Province with the assistance of the Ministry of Plantation

Industries. Minister Mahinda Samarasinghe is keen on expanding the

rubber industry in different parts of the island. Under the project

Palali, Vavuniya, Kilinochchi and Ampara have been selected to cultivate

rubber. This year's target is to distribute 12,000 clones to cultivators

free. Rubber trees have a cooling effect on the environment. When

cultivating rubber, it will be a boon in the Dry Zone where the climate

is dry and rain is not regular.

Extra income

Rubber cultivators can generate extra income during the immature

period of rubber plantation by integration of other crops. Crops

suitable for inter-cropping during the immature phase of rubber are

banana, pineapple, passion fruit, sugarcane, cardamom, vanilla and

cocoa. Growing anthurium under mature rubber trees provides an

additional income to the rubber planters.

The shade provided by the trees reduce the cost of artificial

shading. The rubber tea inter-crop is well suited to the wetter regions

where sole cropping of both rubber and tea is practised. Under normal

circumstances, rubber cannot be tapped very often during the rainy

season and farmers can still obtain an income from tea harvests. Also in

large estates, the inter-crop secures job opportunities for estate

workers.

The RRI has introduced a new rain-guard system which enables to tap

rubber even on rainy days. The rain guarding technology introduced to

the industry is a grower-friendly and it is highly economical.

The RRI has also introduced a technically improved tapping knife

which can tap latex without damaging the tree. It also helps to extract

maximum quantity of latex.

The new tapping knife is available at the RRI in Agalawatte and board

office and Rubber chemistry laboratories in Ratmalana.

There are several challenges confronted by the natural rubber

industry in the world. Synthetic rubber has become a big challenge and

it has captured the major part of the world market.

However, there is a resurgence in rubber plantation because more and

more people are planting rubber because there is a ready market in the

world. |