|

Looking back

Industrial Revolution - Part II

Last week’s article titled

‘Winds of change’ would have enlightened you about the Industrial

Revolution that began in Britain and swept through the rest of the world

eventually.

Today too we feature more valuable information about these

revolutionary changes that started way back in the 18th century, paving

the way for the comforts and benefits we enjoy today.

As

we explained in our previous article, the Industrial Revolution was a

time of invention and new developments. As a result of it, over a space

of just a few decades, individual producers of crops, textile, iron and

other products were replaced by modern factories and farms. Machinery

and goods were made of durable materials such as steel and iron and new

sources of power to operate these machines were introduced. As

we explained in our previous article, the Industrial Revolution was a

time of invention and new developments. As a result of it, over a space

of just a few decades, individual producers of crops, textile, iron and

other products were replaced by modern factories and farms. Machinery

and goods were made of durable materials such as steel and iron and new

sources of power to operate these machines were introduced.

The wide-ranging changes resulted in cheaper goods and a comfortable

life. However, it also led to pollution on a wide scale, health hazards

and dull working conditions. Child labour was one of the major negative

impacts of it.

But, despite the negative impacts, it is thanks to the Industrial

Revolution that today we enjoy modern-day items such as the electric

light, the telephone, the aeroplane and also the scientific technology

that enables sending astronauts into space.

The Industrial Revolution was a time of bold inventions. During that

time, many of the inventors had to face criticism from the public and

also face hardship before their work or inventions were recognised and

accepted.When new ways to produce goods on a larger scale, and at lower

prices were introduced, following the various techniques and machinery

deviced by the then inventors, some of the people were reluctant to

accept these changes. One of the major reasons for this opposition to

the sweeping changes was the fact that machines replaced humans and

deprived many of employment. In fact, in 1811 factory owners in

Nottingham were sent threatening letters by a secret group of people.

The group was nicknamed the Luddites. They broke into factories and

destroyed machinery.

The Industrial Revolution continues even today with each new

development in industry and technology we face. So, let’s check out

details about some of the inventors who were responsible for these

changes that have made such a change in the way we live today!

Abraham Darby

Born - April 14 1678 in Dudley, Worcestershire, England.

Died - March 8. 1717

|

|

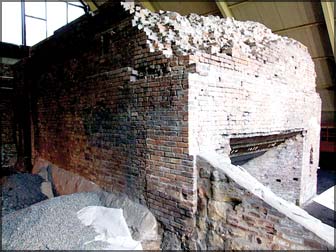

Coke burning

blast furnace |

This

English engineer is considered to be the cornerstone of the Industrial

Revolution by many as his development of a method to use coke for

smelting rather than charcoal and wood enabled advanced mass production

of iron and brass items.He invented the coke burning blast furnace in

1709. Coke is a derivative (something developed) of coal which is

produced by heating the coal and removing the sulphur and combustible

impurities from it. Coke delivered hotter, more sustainable heat without

flame. This

English engineer is considered to be the cornerstone of the Industrial

Revolution by many as his development of a method to use coke for

smelting rather than charcoal and wood enabled advanced mass production

of iron and brass items.He invented the coke burning blast furnace in

1709. Coke is a derivative (something developed) of coal which is

produced by heating the coal and removing the sulphur and combustible

impurities from it. Coke delivered hotter, more sustainable heat without

flame.

Improvements to this coke furnace later led to the evolution of the

iron and steel industry which in turn spawned aircraft, automobile and

ship building industries and also other construction work using these

durable materials.

In the 17th century, charcoal was the leading fuel used for stoking

(feeding furnaces). As more and more coal was needed to keep the

furnaces burning continuously, Darby’s blast furnace fuelled by coke was

an important breakthrough.

Eli Whitney

Born - December 8, 1765 in Westboro, Massachusetts,USA

Died - January 8, 1825.

|

|

Model of a

cotton gin |

Prior

to the Industrial Revolution, farmers in the southern part of the United

States had been growing cotton since the 17th century as the warm, humid

climate was ideal for it. Cotton was one of the growing raw materials

used for clothing. It was grown in huge plantations, but the farmers

could not find a way of processing large amounts of this cotton, keeping

pace with the growing demand for cotton. Prior

to the Industrial Revolution, farmers in the southern part of the United

States had been growing cotton since the 17th century as the warm, humid

climate was ideal for it. Cotton was one of the growing raw materials

used for clothing. It was grown in huge plantations, but the farmers

could not find a way of processing large amounts of this cotton, keeping

pace with the growing demand for cotton.

Slaves were shipped in from Africa to work on the plantations, but

hundreds of man-hours were wasted to separate cotton seeds from the

cotton fibre. Eli Whitney’s development of a cotton gin - a machine

which could generate up to 50 lbs of cleaned cotton on a daily basis in

1793, resulted in a breakthrough for the American cotton producers.

Whitney’s device changed farming in America almost overnight, making

United States the world’s leading cotton producer.

The cotton gin was the first device that helped clean short staple

cotton which was produced in the United States.

A machine known as the Chakra was used in East India to separate

long-staple cotton grown in that region.Whitney’s cotton gin was

improved upon later with horse-powered and water-powered gins to

increase production. As a result cotton became cheaper and the number

one selling textile. Great Britain became the most important market for

American cotton.

Thomas Newcomen

Born - February, 1664 in Dartmouth, Devon England.

Died - August 5, 1729

|

|

Drawing of

the steam engine |

He perfected a practical steam engine for pumping water and is

regarded as a forefather of the Industrial Revolution.

Newcomen’s steam engine is believed to have been developed around

1710. He is said to have combined the ideas of Thomas Savery and Denis

Papin to create his steam engine.

The Newcomen’s engine remained without any changes for about three

quarters of a century and spread not only in the UK, but also to

mainland Europe.

Even though his machine was by no means efficient it was useful at

the time of invention. It was however gradually replaced after 1775

(especially in areas where coal was expensive). An improved design was

introduced by James Watt.

James Hargreaves

Born - April 22, 1720 in Knuzden Brook, Oswaldtwistel, Lancashire,

England.

Died - 1778

According to some reports, this English weaver and carpenter (who was

also known as Hargraves) had got the idea to design the spinning jenny

after seeing a one thread wheel overturned upon the floor.

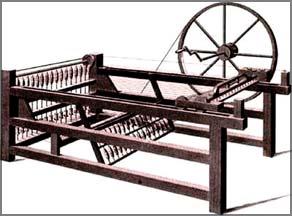

|

|

Model of the

Spinning Jenny |

He

had noticed how both the wheel and spindle continued to work and

realised that if a number of spindles were placed upright, side by side,

not just one, but several threads could be spun at once. So, he had

improved upon the normal spinning wheel and come up with the

eight-spindles spinning Jenny in 1764. He

had noticed how both the wheel and spindle continued to work and

realised that if a number of spindles were placed upright, side by side,

not just one, but several threads could be spun at once. So, he had

improved upon the normal spinning wheel and come up with the

eight-spindles spinning Jenny in 1764.

Some claim that Hargreaves called his new invention the spinning

Jennifer originally after his daughter while others say it was named

after his wife.

However, by 1768, the invention was called the spinning Jenny.

Even though Hargreaves’ invention was unique, he could not obtain

patent rights for it since he had already marketed his product prior to

his application. But, on July 12, 1770 Hargreaves managed to get patent

rights for a 16 spindle machine he designed.

What’s interesting is that Hargreaves, who went down in history for

his ingenious invention was a person who had received no formal

education. He was never taught how to read or write, but he reached

great heights in life as a result of perseverance.He was not ‘spoon fed’

but self-taught. His invention paved the way for a mechanised textile

industry.

Sir Humphrey Davy

Born - December 17, 1778 in Penzance, Cornwall, England.

Died - May 29, 1829

|

|

Miner’s

safety lamp |

He

was a British chemist known for his numerous experiments in electro

chemicals. He is known as the ‘Father of electrolysis’. His expertise in

the field was sought by a group of miners from Newcastle when mining

disasters caused by explosions began to grow during that time. He

was a British chemist known for his numerous experiments in electro

chemicals. He is known as the ‘Father of electrolysis’. His expertise in

the field was sought by a group of miners from Newcastle when mining

disasters caused by explosions began to grow during that time.

With the growing demand for coal, mines were dug deeper and deeper.

This resulted in risks. One obvious risk was that the mines themselves

could collapse and the other was that methane gas and coal dust (both

highly inflammable) could collect in the deep mines and trigger

explosions when they came into contact with a miner’s candle or spark

from a metal tool.

As Humphrey was knowledgeable about gases, he was approached after an

explosion killed 92 men and boys.

He is credited with designing the first miner’s safety lamp. This

lamp was built with a wire mesh which screened the flame and prevented

sparks from escaping.

He is responsible for the discovery of the anaesthetic effect of

nitrous oxide in 1799 which was a major contribution to surgery.He

became a fellow of the Royal Society in 1803, was knighted in 1812 and

became a baronet in 1818.

His Davy lamp became famous. However he’s not the only person to

design a safety lamp. Even George Stephenson designed one. |