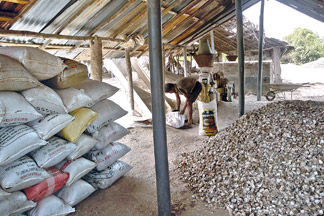

Seashell processing underway in Kinniya

By Mohammed NAALIR

Dried seashells at the plant premises. |

A site |

The Kinniya Divisional Secretariat Division, in the Trincomalee

district is known for its identical resources such as fish and

seashells. A large number of people are engaged in the fisheries and

seashell processing industry.

The low income people in this area collect seashells earn their daily

living. The people who are engaged in this industry earn sufficient

income. A 50-pack of seashells is Rs. 100. A person earns more than Rs.

1,500 a day. The seashell processing industry provides indirect

employment to a large number of people in Kinniya and its surroundings.

The Kinniya Bridge plays a pivotal role in bridging the territorial

gap and improving the economy of the region. The transport of raw

material other products are taking place smoothly.

The seashell processing industry attracts a large number of industry

as it is a viable business.

A.G.M. Najaath, Managing Director, Crescent Farm Tec, engaged in the

seashell processing industry in Kinniya said that during 1996 he started

the seashell processing industry with the support of a person from

Hambantota. In the earlier days only a few were involved in this

industry. By the lapse of time it has become a common industry in the

region.

Najaath said that in the initial days only two persons were operating

seashell grinding plants. The number of plants increased with the advent

of new investors. Day by day a considerable number of investors emerge

in this industry. Now it has become a threat to the environment.

"The Fisheries and Aquatic Resources Development Ministry has granted

permission to run this industry", Najaath said.

Earlier the seashell processors were granted permission to transport

3,000 packs of seashell per month, each with 50 kilos. With the advent

of new investors the Fisheries Ministry limited the permission to 3,000

packs seashell for three months. Now they decreased it to 1,200 packs.

No one can transport seashells above this limit.

"Now the relevant authorities have limited the permission to ten

persons only to protect the environment" Najaath said.

The Government has granted permission to grind only 2,000 packs of

seashells per month", Najaath said.

Najaath has 33 seashell grinding plants in Kinniya. Each has the

capacity to grind from 30 to 50 packs of seashell per day. Depending on

the availability of seashells this amount may differ.

Besides certain days there will be no work in the plant. The people

work in the plant from 15 to 20 days per month. Seashell is brought to

the grinding plant from Thambalagamuwa bay. There are enough shell

deposits in the bay.

There is a mangrove forest in the Thambalagamuwa bay. Mangrove plants

facilitate the snail breeding in the bay, according to Najaath.

Najaath said that snail breeding takes place in the sunny days.

During the rainy season as the fresh water mix with salt water snails

perish. The dead snails become seashells. Due to under water current

these shells are pulled and remain in the gaps of mangrove plants, by

the lapse of time they turn into deposits.

|

| A worker

operating the grinding machine. |

Grinded materials |

Najaath has given employment to more than 250 persons directly and

indirectly in his plant. Altogether 8 persons work in a grinding plant

including the persons who go to collect seashell.

Najaath said that even though collecting seashells is a difficult

job, it is lucrative business to the people in the area.

One can collect nearly 30 packs of seashells per day. Two persons

will be engaged in the seashell collecting process. Each person will

earn over Rs. 1,800 per day.

As the seashell processing is a small industry, the deployment of

giant machineries in this industry will not be beneficial.

The labour problems and low price for the products are other issues

faced by this industry, Najaath pointed out.

As these resources are limited, the continuous collection will

endanger these resources. If these resources want to be protected

additional permission should not be granted to start seashell processing

centres. Enough room must be left to new snail breedings.

"NARA has given us a maximum limit to the seashell processors. They

can't exceed that limit of 20,000 packs of shells per month. The

Government has made this restriction to protect the natural resources.

Exceeding this limit will cause severe environmental problems by the

lapse of time", Najaath said.

These resources should be protected for the next generation. Or else

this industry will have a natural death. It will be a great loss to the

country as well as the industrialists in the field, he said.

If we consumed all these resources we will happen to import dicalcium

phosphate instead of seashell. One kilo is Rs. 160 in the market.

A huge amount of money should have to be spent on the imports of

dicalcium phosphate. Maximum effort should be taken to protect this

resource.

Granting additional permissions to start seashell grinding plants

will further worsen the situation. The existing plants are enough to

cater to the local demand.

Najaath is marketing his products in the Coconut Triangle Zones,

Kandy, Avissavella, Colombo and Kalutara district. He gives prominence

to the Coconut Triangle Zone as there is a large number of Poultry

farms.

"This industry cannot be operated on a large scale. Moving little by

little will help improve this industry. Experience is the only asset to

uplift this industry", Najaath said.

Naajath said that they have formed a society comprising 40 seashell

grinding plant operators to protect their benefits and privileges.

This society is working round the clock to catch a permanent market

place for their products. This society will hold progressive review

meetings once every month. Depending on the necessity the society will

summon special meetings on short notice.

The responsible officers should come forward to solve the transport

problems of seashell processors in the area, Najaath said.

Sahithuraipillai, a fisherman in Nandukkuda said that the people in

this area collect seashell on behalf of seashell grinding plants. For

more than ten years they are doing this job. Nearly 50 in Nandukkuda are

doing this business. They earn more than Rs. 2,000 per day.

Environmental problems also arose because of this activity. Earlier, the

fishermen in the area raised alarm that continuous collecting of

seashells will affect the fisheries industry as the fish breeding will

reduce. Certain faction cautioned that epidemic will spread in this area

while polluting the environment.

He said that in the earlier days they could collect shells in the

shallow waters. Now seashells are available below from five feet to six

feet depth. Earlier days a large number of boats went to collect shells.

Now it has declined to below 150.

Collecting seashells has become very difficult. If this activity

continued the valuable resource will end in due course.

Ishak, a worker at the shell processing centre, said that, crushing

the shells is not an easy job, anyhow it is lucrative. Ishak has the

ability to process nearly 70 bags of shell. He receives Rs. 30 to crush

a 50 kilo seashell bag.

Raikan who is working in a seashell processing centre, said that he

has the ability to process 80 packs of seashell per day. He earns more

than Rs. 2,400 per day.Only the dried seashells will be used to process.

The wet shells will be dried for one day, the next day it will be used

to process.

He said that each person will bring 30 to 35 packs of seashells to

the plant. |