Fillip for mechanisation of tea industry

By Gamini Warushamana

|

The new generation of tea pluckers in uniforms and equipped

with shears at Alton Estate, Talawakele

Pix: Susantha Wijegunasekera |

A project to popularise machinery in tea smallholdings was launched

by the Ministry of Plantations recently.

On a proposal of the Ministry, the Government allocated Rs.100

million for the purpose in 2013 Budget considering the serious issues

the tea industry faced as a result of the acute labour shortage.

Of the Rs.100 million, Rs. 67.5 million has been allocated for

awareness, training and supply of machines to selected smallholder

societies and factories and the balance Rs.32.5 million for research and

development on harvesting machines.

The Government disbursed Rs. 40 million and the Tea Research

Institute (TRI) has launched a program to train tea smallholders in the

use of new machinery under phase I of the program, .

Chairman of the Tea Research Board, Dr. Gerry Jayawardena said that

the investment in the tea industry would ensure the sustainability of

the industry. There was a threat of collapse of the tea industry in the

long run as a result of a severe labour shortage.

“This issue is common in the agriculture sector today and as a former

Director General of Agriculture I have experienced how mechanisation

could change the situation, specially our experience in paddy farming,”

he said.

|

Dr. M.A. Wijeratne (left) demonstrates the new plucking

basket |

“We made this proposal in the 2013 Budget and we have got the money.

This initiative will improve labour productivity and change the attitude

of the younger generation on plantation jobs,” Dr. Jayawardena said.

Senior Research Officer and the Officer-In-Charge of the TRI Low

Country Regional Centre, Ratnapura, Dr. M.A. Wijeratne said that in the

initial phase, 50 tea smallholder societies and 25 private tea factories

have been selected for the project covering all tea growing regions.

This training of trainers program is being conducted at the Ratnapura

regional centre.

It is a two-day residential training on the use of plucking shears

and machines. Two members from each society and Tea Inspectors of the

Tea Smallholding Development Authority will participate and 150 trainers

will be trained initially.

Training will be conducted on the use of tea plucking, pruning and

holing machines.

There are three machines for tea harvesting. The manually operated

shears, suitable for small tea lands, can double the output.

The battery-powered small machine can increase output by three times

and the large petrol machine can increase output five times.

A labourer can prune 250 tea bushes a day manually and with the

pruning machine this will be increased to 800-1,000 bushes a day.

The holing machine can increase labour productivity by over five

times. Dr. Wijeratne said that the training conducted irrespective of

gender and women received the training in operating all the machines.

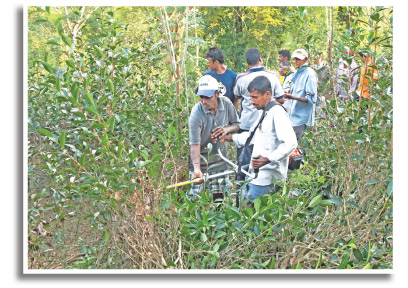

|

Field training in progress |

The second level training will be launched in March and is expected

to create a huge impact on the tea smallholdings sector including

attitude change and forming of new service providers for harvesting,

pruning and holing.

The TRI provides a 50 percent subsidy to tea smallholders to purchase

the machines. Each society will get 10 shears, 10 baskets, one motorised

plucking machine, one battery operated plucking machine, one pruning

machine, one holing machine, worker overalls and safety gear which cost

around Rs. 350,000.

Dr. Wijeratne said that out of around 200,000 hectares of tea lands

in Sri Lanka 58% are smallholdings.

According to 2012 statistics the total tea production was 326 million

kilos and the estimated average production was about 1,600 kilos per

hectare per year.

Low productivity, high cost of production and declining quality are

the key issues faced by the tea industry today.

These issues are greatly related to lack of labour, high cost of

input and lack of mechanisation of labour intensive cultivation

practices such as plucking and pruning.

Plucking (harvesting of tea) is considered to be the most labour

intensive field operation in tea cultivation. More than 70 percent of

the workforce in a plantation is employed daily for plucking while about

35-40 percent of the total cost of production comprises cost of

harvesting.

More importantly, plucking policies influence growth, yield and

quality of the end product. Due to lack of workers, some tea estates are

either harvested at extended plucking rounds leading to loss of crop and

quality or are permanently abandoned leading to heavy crop losses to

estates.

Extended rounds can reduce tea crop by more than 20 percent. Due to

the nature of plucking operations in the field and due to fatigue, young

workers keep away from estate work. The quality of the end product is

affected when the harvested crop comprises of more coarse leaves (mature

shoots) due to delayed harvesting.

Being a major tea growing country with more than 95 percent of

production exported securing a premium prices in the world market, it is

extremely necessary to produce top quality tea, he said.

|

The machines that increase labour productivity |

A majority of the tea produced come from tea smallholdings, estimated

to be around 400,000. Although, it is expected that harvesting of

smallholdings is carried out by family labour, many use hired labour,

some of whom come from nearby estates.

This also has been identified as one of the causes for absenteeism of

workers in corporate sector tea estates.

In addition, corporate sector estates also face problems in finding

labour for their field practices.

Therefore, mechanisation of plucking has been identified as an urgent

need for ensuring sustainability of the tea industry, he said.

Dr. Wijeratne said that there is a rapid increase in mechanisation of

tea cultivation in the corporate sector.

Mechanised tea harvesting was initially implemented at Gawaravila

Estate, Hatton and at Alton Eastate in Talawakele and thereafter, in

many other plantation companies.

Today Grayton Estate, Kotagala has fully mechanised tea harvesting.

Evidence clearly demonstrates that mechanisation contributes greatly to

increase productivity and the quality of tea, he said.

Project activities and the training of trainer program is led by Dr.

Wijeratne and coordinated by the Officer-in-Charge, TRI Deniyaya centre,

Saman Ratnayake. |